Dynamics AX 2009 – 助力信嘉机械铸造有限公司智能化制造

行业:高端制造,离散制造

2014年11月23日下午4点00分 | 2732

客户资料

信嘉机械铸造(昆山)有限公司由信嘉香港有限公司投资,成立于1996年,有近二十年的历史,专业从事高品质钢铁铸造及其后期机械加工处理的企业。

项目背景

信嘉机械铸造(昆山)有限公司由信嘉香港有限公司投资,成立于1996年,有近二十年的历史,公司从1997年7月投入生产,专业从事高品质钢铁铸造及其后期机械加工处理的企业。

信嘉机械铸造有限公司(SC)位于江苏省昆山市,占地总面积37,000平方米。信嘉拥有近10,000平方米的铸造车间,2,600平方米的机械加工车间,以及近400名员工的人资力量。

信嘉的球墨铸铁,高强度火球铁,合金铸铁,灰铸铁等一系列优良产品远销台湾,日本,欧美等主要市场,在行业享有很高的品牌信誉

厦门一维天地为其提供Dynamics AX2009 实施服务,双方的愉快和深层次合作,推进信嘉机械信息化建设提高和完善不仅保证系统日常正常运维,同时提供功能培训、业务流程持续改进方案、 财务报表审计咨询,IT系统建设规划与咨询等;一维天地的铸造行业解决方案和IT信息化咨询与管理丰富经验得到信嘉机械的高度认可;

解决方案

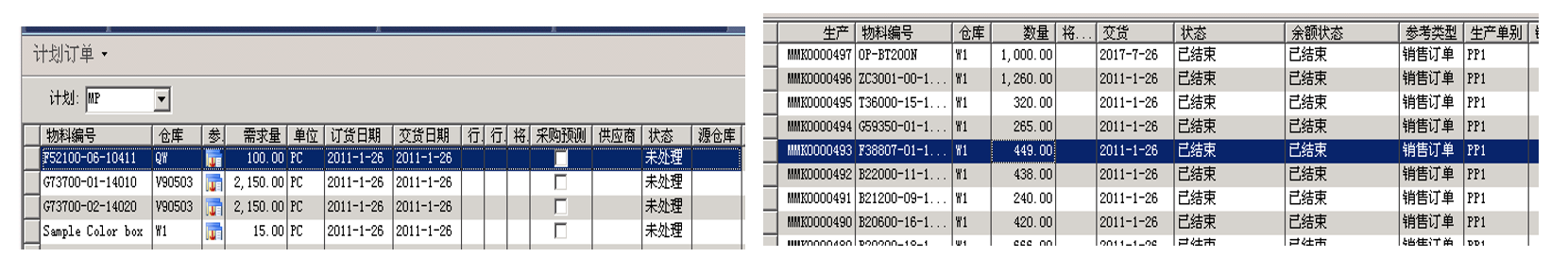

信嘉机械采用Microsoft Dynamics AX 2009 ERP系统对公司所有业务流程及信息化平台进行全面整合。实施内容包括产品数据管理,销售,供应链,主计划,库存管理,生产管理,PDA移动仓储管理,财务,管理分析报表等。为企业管理者及员工带来他们所需的洞察力,连接性和专业工具

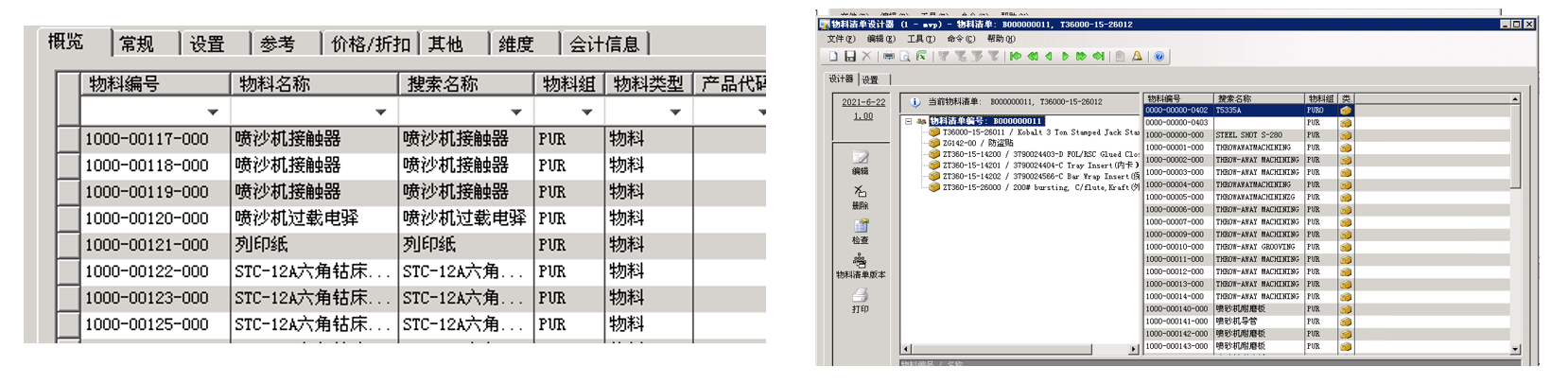

机械制造的产品数据管理:机械制造行业产品物料清单复杂,材料参数众多,生产工序繁复,工艺过程参数极为重要,数据正确管理、传递尤为重要。通过Microsoft Dynamics AX平台整合所有的产品数据,无论多复杂的BOM和工艺路线都能通过Dynamics AX有效管理,且能够对物料清单及工艺路线的多版本进行区分管理。同时将所有产品生产参数通过系统统一管理,且能够通物料清单、工艺路线、品质管理紧密集成,并通过系统传递生产现场,使生产安排及生产执行无缝集成。指导车间人员准确操作。

制造执行管理:通过Dynamics AX 生产管理功能和生产现场MES管理系统集成,清晰指导生产现场作业安排并有效监控生产现场工时汇报。同时同财务成本核算及人力资源考勤管理结合,实现生产人工成本及制造费用的精准核算。

财务业务一体化:通过Dynamics AX 实现财务业务的无缝集成。所有财务数据通过业务数据自动生成,提升财务管理的准确性及及时性。

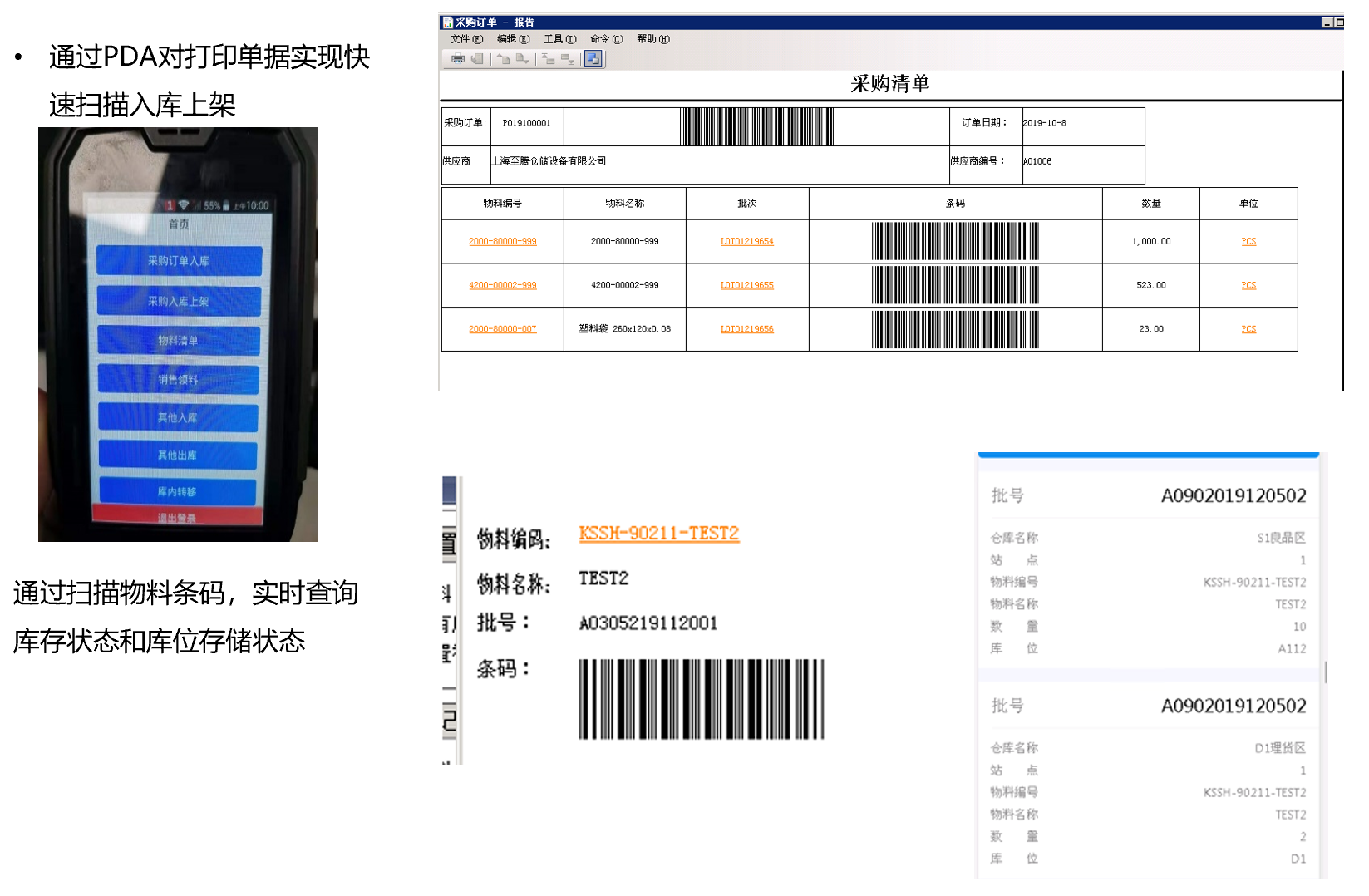

仓储物流管理系统:通过自研物流仓储系统,快速实现仓库科学化管理,从而提质增效、节省人力、降低成本;主要是通过入库、出库、调拨等有效控制以及仓库作业、物流成本追踪,来达到目标。通过条码管理对物料的进出和库位条码管理,精准实时获取库存信息,实现库存缩短从接受订货到发货的时间;库存适量化;提高搬运作业效率;提高运输效率;使接受订货和发出订货更为省力;提高订单处理的精度;防止发货,配送出现差错;调整需求和供给;提供信息咨询等。

商业收益

Microsoft Dynamics AX 的成功上线将信嘉机械的人、物、供、销及相应的物流、信息流、资金流、业务流等紧密地集成起来,实现资源优化和共享,大大提升公司管理能力以及工作效率,大大提升企业的核心竞争能力,为信嘉机械未来的高速发展打下坚实的基础。

Microsoft Dynamics AX系统强大的功能,在销售、采购、库存等业务方面实现了财务业务的全面一体化,信息化的全面整合。各类管理报表为管理层的决策提供强有力的支撑。不但为企业稳固了业务运作流程,而且为企业的发展的提供了巨大的支持。

▪ 消除了信息孤岛,提高客户满意度;

▪ 优化及固化了企业业务流程的运作,标准化的业务操作,减少了对人员的依赖思想;

▪ 提高生产力,企业内部管理效率较大改善;

▪ 可视化,准确、快速、多维度的报表分析;

关于 Microsoft Dynamics AX

Microsoft Dynamics AX 为全球的制造公司和分销公司提供了一个全面的商务管理解决方案,该解决方案能帮助他们更高效地管理其广泛的业务领域,包括零售数据和财务分析,并特别注重实现整个供应链的综合实时可见性。这个集成的、可定制的解决方案通过以下优势来创造商业价值:

▪ 加强企业的洞察力以帮助做出合理的决策,提供企业管理各类数据的可见性

▪ 扩展数据和关键流程,以加强与客户和合作伙伴的重要关系,不论其使用什么样的系统,不管其复杂程度如何

▪ 通过与现有的企业 ERP 系统和 Microsoft 产品家族的平滑集成,实现技术投资回报的最大化

▪ 通过流程的优化和自动化,以提高生产力,优化供应链,从而降低成本,提高赢利水平能力

▪ 可以进行定制以满足当前需求,易于把握新商机,并能更容易地达到客户的个性化要求,从而在竞争中胜出

更多信息

如若希望获得关于微软产品和服务的更多信息,请拨打微软客户服务热线800-820-3800,或浏览微软(中国)有限公司网站: http://www.microsoft.com/china/dynamics

如若希望获得关于微软金牌合作伙伴一维天地的更多信息,请访问其公司网站:http://www.iwstech.com