沙迪克新横(厦门)机械有限公司Dynamics AX--ERP项目

行业:高端制造

2010年8月2日凌晨12点00分 | 3979

日本株式会社沙迪克是世界最大的放电加工机生产厂商之一,并拥有世界一流的线性马达生产技术与纳米加工技术,2005年公司年销售额达49亿元人民币,产品远销海外大部分国家和地区。

沙迪克(厦门)有限公司成立于2006年4月,地址位于海沧新阳工业区,总投资额达9000万美元,预计年销售额可达8000万美元,是目前国内最大且最专业的放电加工机生产厂商之一,主要从事研发、生产高精度数控放电加工机、数控加工中心、线性马达、陶瓷构件等产品,产品用于汽车产业、数码相机、手机、液晶显示屏等精密模具加工领域。

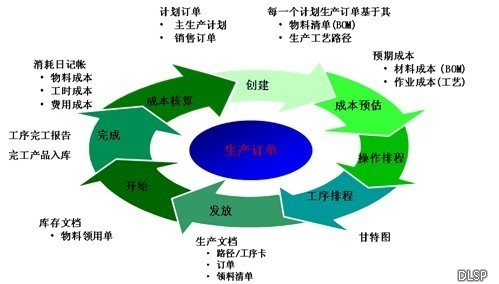

为了有效解决生产计划管理,生产生命周期管理、生产现场管理,实现即时制(JIT)制造,加强财务成本的管理。沙迪克采用微软Dynamics AX 2009中的销售订单、生产订单、采购订单来跟踪管理企业经营的全过程,并以这三种订单产生企业资源计划。销售订单主要是用于确认客户需求、触发生产,并跟踪客户需求的完成情况。生产订单是生产指令,根据销售订单或预测来产生,在每一生产订单明确产品的物料编号、数量、交期、BOM及生产工艺,系统通过生产订单来管理生产,明确生产任务,归集、分析生产成本,同一生产订单的不同生产工序,又可派生出不同的作业卡片,通过生产订单,你可以查询订单各工序的生产计划与进度,便于及时调整生产安排,确保按时交货。采购订单由生产订单触发,主要用于跟踪原材料的供应情况,了解原材料是否按时到货,会否影响生产计划。

系统根据销售订单量的多少,按经济批量对销售订单进行拆单或并单生产,并以生产订单为指令发放给各车间,各车间只按生产订单要求的数量、交期来安排生产。另外,为了便于同一生产订单不同工序的分开记录和汇报,系统根据生产订单上的工艺路径,产生各工序的生产作业卡片,车间管理员只需把各作业卡片发放给各作业岗位工人,以此驱动生产运行,作业员根据实际的完工产量填写作业卡片,按班进行生产汇报产量、工时。为了保证产品的可追溯性,在移转过程中,原则上不允许合批,如出现分批,必须拆分流转卡。从而实现精细化的生产订单生命周期管理,如图:

一维天地作为微软ERP软件的金牌合作伙伴,凭借丰富的行业经验和完善的服务,获得了沙迪克新横(厦门)机械有限公司的充分认可。

一维天地将运用微软Dynamics AX 平台强大的整合能力,为沙迪克提供基础地微软软件生态系统的一揽子解决方案,为沙迪克搭建智能型的信息化管理平台。

此次的成功合作将促进沙迪克新横的信息化建设,完善其生产、仓储管理,并通过微软的灵动制造系统,实现其动态供应链的需求,从而助力线性马达生产技术的高速发展。

商业收益

Microsoft Dynamics AX 的成功上线将沙迪克的人、物、供、销及相应的物流、信息流、资金流、业务流等紧密地集成起来,实现资源优化和共享,大大提升公司管理能力以及工作效率,大大提升企业的核心竞争能力,为沙迪克未来的高速发展打下坚实的基础。

Microsoft Dynamics AX 系统强大的功能,在销售、采购、库存等业务方面实现了财务业务的全面一体化,信息化的全面整合。各类管理报表为管理层的决策提供强有力的支撑。不但为企业稳固了业务运作流程,而且为企业的发展的提供了巨大的支持。

▪ 通过业务自动化实现更好的信息管理;

▪ 有效的工作流程可以提高工作效率;

▪ 集中数据可以确保更高的效率;

▪ 简化各项核算过程;

▪ 消除信息孤岛与数据冗余

▪ 提高客户满意度

▪ 提高后勤部门工作效率,理顺各种流程

关于 Microsoft Dynamics AX

Microsoft Dynamics AX 为全球的制造公司和分销公司提供了一个全面的商务管理解决方案,该解决方案能帮助他们更高效地管理其广泛的业务领域,包括零售数据和财务分析,并特别注重实现整个供应链的综合实时可见性。这个集成的、可定制的解决方案通过以下优势来创造商业价值:

▪ 加强企业的洞察力以帮助做出合理的决策,提供企业管理各类数据的可见性

▪ 扩展数据和关键流程,以加强与客户和合作伙伴的重要关系,不论其使用什么样的系统,不管其复杂程度如何

▪ 通过与现有的企业 ERP 系统和 Microsoft 产品家族的平滑集成,实现技术投资回报的最大化

▪ 通过流程的优化和自动化,以提高生产力,优化供应链,从而降低成本,提高赢利水平能力

▪ 可以进行定制以满足当前需求,易于把握新商机,并能更容易地达到客户的个性化要求,从而在竞争中胜出

更多信息

如若希望获得关于微软产品和服务的更多信息,请拨打微软客户服务热线800-820-3800,或浏览微软(中国)有限公司网站: http://www.microsoft.com/china/dynamics

如若希望获得关于微软金牌合作伙伴一维天地的更多信息,请访问其公司网站:http://www.iwstech.com