IWS借助CPC大会向全球展示自动仓储3.0解决方案

2017年11月6日凌晨12点00分| IWS | 2941

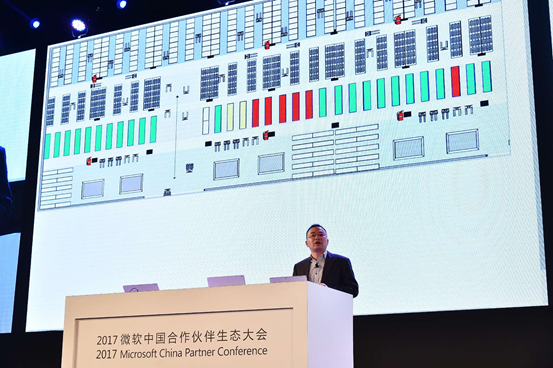

金秋时节,FY17 “微软合作伙伴大会”(CPC)在北京召开,厦门一维天地黄总应邀出席并且为大会带去了自动仓储3.0的方案演讲,备受好评。

一维天地,Dynamics 忠诚的朋友,十几年如一日,充当ERP的传道士。一直以来,我们都专注于ERP解决方案,现在,随着工业4.0的发展,我们也基于Dynamics推出新的自动仓储管理解决方案。

自动仓储,这是一个贵族产品,是一个高大上的自动化的立体仓库,它好是好,就是太烧钱,从1.0的孤立管账模式到2.0的供应链联动集成,其侧重点都是在于账务处理,并没有真正解放仓库人员的工作,提升其作业效率。仓库3.0,核心是用信息系统充当人的大脑,把“人当机器”,库位的分配、拣货不在依赖于仓管人员的经验,而是由系统自动计算作业路径。好比,有1000箱货要入库,系统将产生每一箱货分配存储库位,不再是搬运工想搬哪就是哪。而仓库4.0,无人仓库的最后一步就是用机器换人,用AGV、传送带换人。

北欧风情,欧洲知名的家居品牌,全球超过60个国家有专卖店,在上海的制造工厂特雷通,拥有6万多平方的仓库,从它的货架、托盘、叉车可以看到,他们的仓库都是传统的设备,和千千万万工厂一样,但经过我们简单改造后,它们都是会聊天的智能设备。

仓库作业列表,由各种库存交易产生,仓管员不再依赖入库单、出库单,完全由它驱动各种仓储作业。

仓管工作员不小心放错了库位,系统将亮红灯给予警示,如果放入的库位正确,系统将亮绿灯完成入库任务。有了它,仓库工作就是这么的简单,搬运工变出租车司机。

通过系统库容分布图,我们还可以一目了然的知道整个仓库的布局、库容情况。

自动仓储3.0包含上架策略计算库位,入库时触发收货、发票、财务记账等一系列动作,这些功能都依赖Dynamics365强大的内核,在数据采集、物联网技术上采用了azure IoT,数据分析展示上采用Power BI, 集智能化、精细化、零操作、平民化四大特点于一身,充分利用现有资源建设,只需小几百万甚至几十万就可以实现。

厦门一维天地,因为坚持所以专业。