高科技电子行业解决方案

行业:高科技电子行业

2013年9月13日凌晨12点00分 | 4324

FPC软式印刷电路板行业特点

一、 FPC软式印刷电路板行业(以下通称为FPC行业),都属于获得订单后再组织生产的经营形态企业,称为订单型生产企业。其生产特点是由客户设计产品的线路图之后,交由印制板企业代工生产。具有订单品种多,订货数量有限,需要时才下订单,对质量要求严格,交货周期短等特点。企业不仅要关注和开发加工技术,同时还要密切配合客户设计师实现设计/工程一体化。此外,因产品设计要求的不同,选用材料、流程控制、工艺参数、加工方式、产品标准均不相同。管理者需要综合应用材料、设备、工艺,实现印制板产品加工,确保产品充分满足电路设计和装箱要求。

二、 FPC制造属于知识、技术密集型行业,科技含量高,与资讯技术结合较为紧密。在当今的FPC行业,资讯技术是主要工具,知识是战略资产,企业信息化的意识越来越强,构建一个企业资源规划的资讯管理系统,已是挑战生存的必由之路。 其中FPC柔性电路板行业的生产特点强调与下游组装工序的整合,对MRP也会有独特的要求。

软式印刷电路板企业ERP系统的特定需求

FPC行业产品特性:FPC行业产品种类繁多。在行业客户群中,每个客户产品都会有不同的产品要求,如尺寸、层数、材质、厚度、产品管制、品质认证等,甚至会出现客户特别指定某个品牌的基板、油墨等,很少会出现共享性产品的情况。这使得FPC除常规对ERP产品的需求外,在产品方面还有一些特殊的管理要求

▲ 周期码管理需求

基于FPC产品质量管理的特点,企业会通过周期码来记录产品的生产批次。而且周期码影响从生产安排到采购购买周期码印刷网版的采购安排到成品入库的整个环节。所以周期码的管理是否有效直接影响FPC企业的生产环节是否合理,高效。

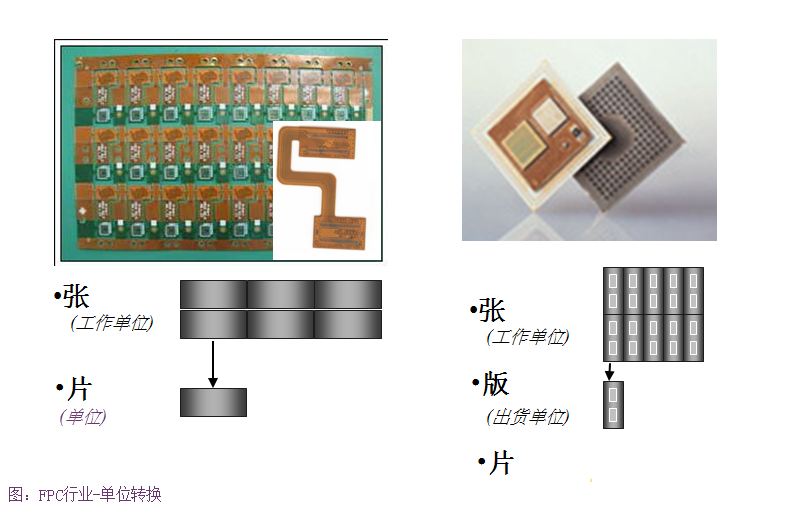

▲ 单位转换的需求

由于FPC行业的主要原材料为基板、铜箔、纤维等,其中基板和铜箔是以张(Sheet)为单位进料,且有不同品牌、尺寸、厚度等参数。待开料裁切以后,将会以生产拼板(Panel)和单只(Pcs)的双计量单位运行,直到生产完成后都有可能以单只或套板的方式分别入库、出货。所以从张(Sheet),到大板(Panel),到单只(Pcs),以及套板(Set,或称XPanel)的计量单位转换,对于生产管理而言都是非常重要的项目。

生产业务特性:FPC行业经常会出现“多了不要,少了不收,下次不用”的订单,因此对于投产数量以及开料张数的正确评定显得非常重要

生产卡管理需求:

● 指定生产分批次生产的卡数及对应流转卡编号

● 打印的工序流转卡上有流转卡号和工序编号

● 在汇报时可以同时汇报工序完成数量及对应卡数编号

● 工程变更需求:FPC行业是一种代工行业,产品的设计变更非常频繁,经常会更改版本。客户一旦更改版本,制造指令和工艺流程卡也要配合变更,甚至可能会出现部分变更,部分不变更的情况。当一个产品有多个版本在现场投产时,ERP软件必须能够协助控制:在旧版本离站前,新版本不得进站,以避免新旧版本同时出现在一个工序中导致混板的情况。

● 替代物料管理需求:FPC行业生产计划管理业务中,产品所用元器件需要有条件互相替代,替代物料的使用可以物料得以充分使用,尤其在计划阶段与生产阶段使计划人员根据物料的替代关系平衡主选物料与备选物料的使用,从而降低库存,替代物料管理的具体需求要点如下:

● 能够在产品BOM中设置物料主料与替代材料;

● 在主计划运行时按主要元件系统自动计算物料需求;

● 在下达生产订单时,可以根据库存变更使用元器件。

● 生产模具治具管理需求:FPC产品生的过程所使用的模具与治具,同产品一样纷繁庞杂,在管理上对其在采购、库存、领用及报废等常规管理需求外,还需要对其使用次数(寿命)以及产能、维修等进行管理,这些管理的信息需要体现在ERP系统当中。

成本业务特性:

FPC行业的成本计算是所有行业中最为特别、最为复杂的,从开料、压板、成形,一直到FQC、包装、完工入库,需要依据每一个工序投入的材料费用、人工费用、制造费用等进行分步核算,再依据订单产品编号分批累计成本。并且不同类型的产品,其工序的标准费率都会有所区别。此外,对于一些产品如盲埋孔板、沉金板、压铜座板,因其工艺或所有材料的特殊性,要求必须对此采用一些特殊的计算方法。在软件设计时必须考虑计算模型的扩展性,而计算模型的设定都会直接影响到WIP成本、成品仓存成本及报废成本的计算与评估。另外,FPC行业成本的计算与销售报价有着密切关系,相关计算模型可以共用。而成本系统与报价系统的关联性也必须在ERP软件中得到体现

基于行业ERP信息化解决方案

企业资源计划(ERP)软件系统已在全世界范围内被广泛应用。许多的公司已经不止一次两次地从信息技术的更新换代中受益。企业投入资金进行ERP系统的重新设计与研发、集成与加速,以便增进业务的绩效。如果我们去访问ERP供应商的网站时,你总是会发现他们提供的ERP系统总是为某个“行业”设计的。原因就是不同的行业的差异要求他们的软件厂商能够创造出一种能适合本行的“垂直”解决方案。微软与其商业伙伴一直在不断努力按照这些行业的特定需求,研发出适合的ERP解决方案,以下即讲述了FPC ERP行业解决方案是如何满足FPC行业的独特需求以及如何成功地支持他们的业务的。

微软ERP总体流程概述

FPC行业ERP解决方案主要特点概述

一、产品数据管理

● 让更多的部门与岗位利用ERP系统存储使用产品数据信息;

● 系统将根据产品主文件中的周期码设置,自动灵活地生成产品的周期码,以实现对成品库存保质期的精确管理及质量跟踪;

● 更加符合业务管理实务的需要;

● 更加方便有效地解决替代的难题。

二、生产管理

● 生产卡式管理:按FPC特性,将销售订单划分为以卡为单位的更小生产单元,实现生产现场的卡式管理。

● 每个产品可以设定张数量、每卡张数、每天生产卡数以及每次投产天数,以便精确协调销售、生产与材料的采购数量。

● 生产汇报管理:对于一个FPC产品的生产过程,不仅包括产品本身的生产,而且还包括了其前道辅助产品,例如铜箔、覆盖膜的生产,如果按通用的ERP系统需要将生产订单拆分成若干子生产订单进行处理,这样无论是生产、计划还是仓库部门都无法对整个产品的生产情况一目了然,因此在解决方案中提供了“生产流程单”控制的方法,在一个生产订单下可以包含若干个流程单,例如“顶层保护膜流程单”、“补强流程单”、“胶纸生产流程单”等。各种半成品、成品的生产情况可以按流程单进行,这样就减少了生产汇报环节操作的步骤,而且大大加减化了成本核算流程。

● 外协加工管理:FPC行业中有大量的生产管理涉及外协加工业务,外协加工业务是一种包含生产、采购、库存的综合业务,解决方案中提供了一个业务数据的综合管理的平台,方便用户对外协物料,加工费用、成本与对账统一管理。

● 模具管理:FPC解决方案实现了FPC行业对模具管理的特定要求,在系统提供的模具的计划与采购流程,申请流程,领用流程,耗用与模具寿命管理流程,报废流程的管理

三:品质管理

质量管理与控制是FPC行业的制造过程中的一个非常重要的方面,在一个原材料入库、生产过程中以及产品发运之前都需要做大量的检测。这就是为什么FPC行业解决方案的质量管理要与制造全过程进行整合的原因。FPC解决方案基于Dynamics AX标准的质量控制与质量管理功能,结合行业特性,开发质量AQL抽样及判断标准,通过系统自动化产生AQL标准下的抽样数量。根据最终的不合格数量判断是否达到AQL的允收标准,由系统给出本批次的检验判定结果。

四:供应商管理库存(VMI)

FPC生产企业对某些经常供货的物料与供应商协商一致采用VMI的方式进行采购,根据实际的使用量来确定采购的数量。

在FPC解决方案中,当主计划运行完成后,系统将同时产生供应商仓库向主仓库转移的订单以及向供应商仓库的采购订单。当仓库确认供应商仓库对主仓库之间的计划转移单时,系统将自动扣除供应商仓库中的库存数量,并同时自动创建一行采购记录并执行收货。每个结算期间(例如按月)对于同一个供应商与供应商做一次结算

五. 成本管理

财务业务一体化

针对物料类别预设好过账规则和存货计价方式,由业务系统自动产生凭证。且每月末可根据实施发生的制造费用按多种规则分摊至生产成本中。

成本追溯调整

针对采购发票与采购账估金额不致的,可以采用追溯调整至原材料、半成品、产成品或销售成本中,满足上市公司对成本追溯调整的要求,同时精确的计算出生产的实际成本。

精确的成本核算

实现对不同工序根据其生产特点采用不同的制造费用及直接人工的分配方案,包括面积分配方案,张数分配方案,工时分配方案及计件工资方案等。

微软ERP概述总体优势、平台优势

FPC垂直解决方案是建立在Microsoft Dynamics AX 之上的。Microsoft Dynamics AX 是现代化的ERP,代表了信息技术与企业管理水平的最高水平。深度的行业物性功能开发与标准的Dynamics AX商务逻辑的集成使得FPC行业实施ERP系统更加的容易,并且有极高的成功率。

微软ERP系统——Dynamics AX与您所熟悉的其他微软产品的工作方式相似,并可与这些产品协同工作,无缝集成OFFICE, SHAREPOINT ,BI等。

● 全面的商务管理解决方案,包括财务,分销、生产管理、客户关系管理、项目成本、人力资源、电子商务。

● 严格的权限设置和审批流程,保证信息的安全和稳定。提供强大的报表工具,给管理层决策提供强有力的支持。

● 先进的工作流和信息沟通平台,确保内部信息沟通的通畅,提高跟单效率。

● 完全的源代码开放