机械制造行业解决方案

行业:机械制造行业

2013年9月13日凌晨12点00分 | 3524

机械制造行业产品结构(BOM),加工工艺(ROUTE)多样复杂,且通常多种生产模式并存。在庞大且多样的产品数据及生产模式下,想要准确有效地进行计划,排产,使用传统的人工处理方式必定难以满足企业发展的需要。同时如何准确的评估产品成本,进行成本分析在面对多样化的数据情况下更是让企业头痛苦恼。

微软Dynamics AX 机械制造行业解决方案集成从基础产品数据管理,产供销,到财务核算的一整条完整的企业管理流程解决方案,通过Dynamics AX ERP系统帮助企业处理多样的数据,满足多种生产模式的差异化管理,提高企业计划排产准确性,提升成本管理能力,从而从内到外提高企业的产品竞争力,市场竞争力,满足客户需求。

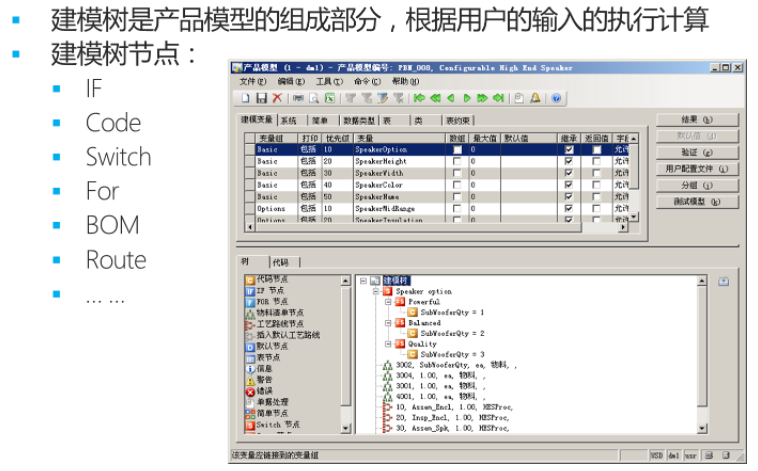

——灵活配置,自动生成BOM,ROUTE的产品设计器

AX机械制造行业解决方案产品设计器功能能够根据自定义的配置条件,自动生成BOM和ROUTE。简单快速响应客户需求,灵活配置不同的组件,减少研发设计人员的数据处理,提升效率。

根据不同的组件条件,可以设置多样化的规则,设计人员进行产品设计,销售人员进行报价或者下达订单时都可根据规则自动生成对应的BOM及ROUTE。

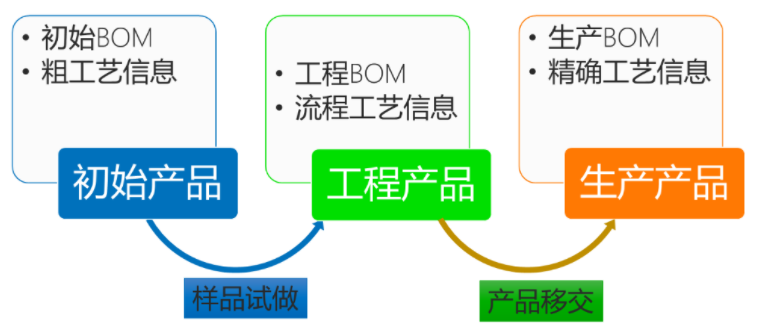

同时,对BOM及ROUTE的多版本管理帮助产品设计人员跟踪整个产品设计过程的变化。从研发,报价,样品,量产不同的BOM及ROUTE的版本使得企业能够更准确的针对不同的需要使用准确的产品数据进行管理。

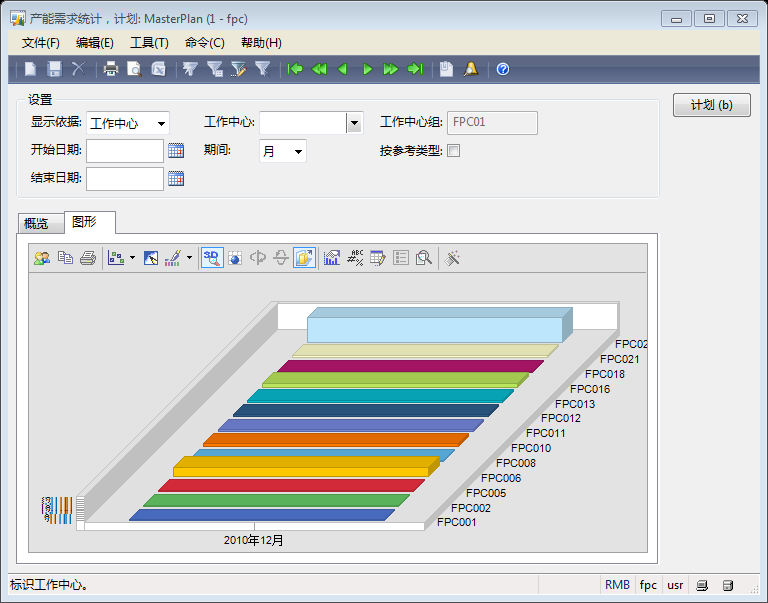

——不同生产模式下的计划,排产

集成AX ERP的高级计划功能,自动化的进行计划排产,帮助企业提升作业效率,合理安排产能。做到适时,适量,适价的完成生产任务。满足客户需求。

无论是按订单生产,按库存生产,计划预测,系统根据多样的计划自定义设置,针对不同的生产模式提供计划安排信息。生产,物料安排人员根据系统产出信息能够合理安排物料需求计划及生产安排计划。

对于设定安全库存的产品,系统会自动对库存低于安全库存的产品生产计划生产订单;对于按订单生产的产品,系统会根据特定订单生成生产计划,同时计划人员也可以随时运行计划检查跟踪计划订单。生产过程中,发生的插单,计划调整等变动情况,计划人员也可以随时更新计划,且AX强大的计划排产功能帮助计划人员可以根据多种计划方向正推或是反推生产计划。

对于机械制造过程中的大型设备,系统生成的计划可以帮助计划人员清楚地查看不同设备的产能情况,掌握整个生产动态,及时调整计划。

——项目制管理

不管是内部研发项目还是外部项目型定制产品。在AX机械制造行业解决方案中,从项目立项,项目预算,到项目过程中的事件,生产过程,项目计划管理,项目交付,项目服务,AX进行了全流程的控制及管理。基于这样的数据构成,为管理人员跟踪项目,分析项目提供了完整,详细的数据支撑。

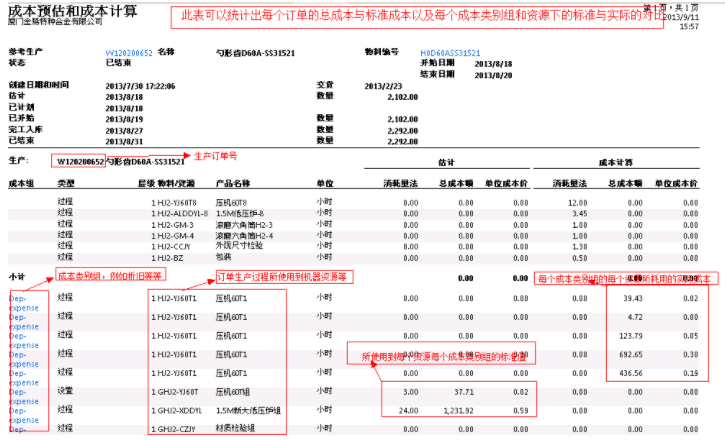

——基于标准与实际比较的精确成本分析

基于AX强大的产品数据管理功能,AX能够对各个产品进行精确的成本核算。成本控制人员可以在产品研发时即根据研发BOM及ROUTE预估产品成本,报价时销售人员可基于产品成本进行报价,实际生产完成后,又可基于产品实际生产投入情况进行实际成本核算。

因为能够便捷快速的更新产品BOM及ROUTE,使得整个成本核算能够基于特定订单的产品构成需要,使得成本更精确。财务人员可以根据多样的报表检查成本分布情况,设计及生产人员能够更有效的改善产品,降低产品成本。