Dynamics AX 冶金行业解决方案

行业:冶金行业

2014年9月16日凌晨12点00分 | 4006

国内冶金行业现状:

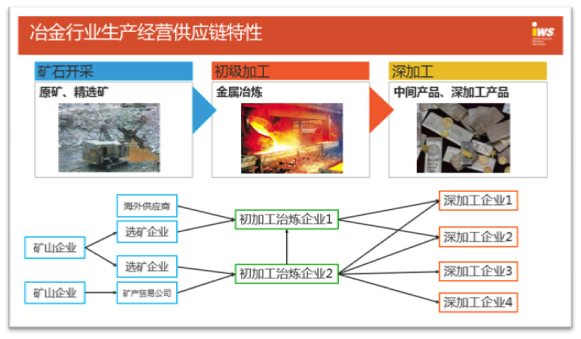

冶金行业从最初单一的金属冶炼分散经营不断向上游矿山采掘及下游金属加工及各种产品制造业延伸,逐步发展成为集采掘业,金属冶炼,中间产品及深加工产品生产、贸易、物流、研发等为一体的集团化运作模式,单个企业间的竞争已被集团与集团间的竞争所代替,但在集团化发展的进程中,管理思想的统一、信息化建设的发展常常滞后于集团化发展的脚步,有时甚至成为企业集团快速发展的羁绊。

国内冶金行业(在企业资源计划管理中)面临的挑战:

财务与业务的一体化

集团化统一管理

行业特性功能的满足

重复建设、信息孤岛

解决方案介绍

概要

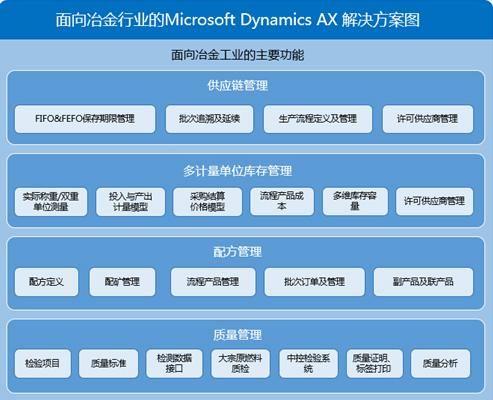

厦门一维天地信息技术有限公司基于微软ERP – Microsoft Dynamics AX2012 基础上,立足国内冶金行业,以供应链、财务为主线、生产、质量及项目管理为重点,研发出针对性的冶金行业信息化解决方案。本方案由销售、采购、库存、生产与计划、配方管理、项目管理、质量管理、会计核算、资金管理、集团财务、人力资源、商务智能等多个主要的子系统构成,提供二次开发平台与源代码,可实现与DCS系统与检测设备等硬件数据源的无缝集成,面向电子商务应用,具有灵活的数据分析功能。

该解决方案是在充分研究冶金行业企业集团的生产制造及经营管理特点的基础上,为冶金行业提供一个功能全面,架构灵活的ERP解决方案,满足冶金行业集团企业管理的需求。

适用客户

冶金全产业链的行业企业:

采掘、采矿业

金属矿产品初级加工企业

金属冶炼企业(湿法、火法)

金属制品、型材制造企业

金属深加工企业

稀土分离

矿山采掘行业解决方案

金属冶炼行业解决方案

中间产品及深加工产品制造行业解决方案

冶金企业集团管理

项目管理

采矿外包管理

矿产品品位管理

矿产品计量与计价

微软项目管理整体解决方案,结合了多个微软的项目管理产品(Office Project Professional, Project Server 及 Dynamics AX Project),创建了一个项目管理协同工作的平台,对企业集团内众多的项目进行信息的收集、加工和传输,用经过处理的信息流指导和控制项目建设的物资流、资金流,满足决策层、管理层、执行层以及相关外部关系对项目管理的不同的信息需求。

项目预测与预算

项目计划编制与控制

项目招投标管理

合同管理

项目采购

项目结算

项目活动管理

项目报告与成本分析

解决方案架构图

典型案例介绍

项目背景

厦门钨业(股票代码:600549),主要从事钨冶炼产品、钨粉末、硬质合金、钨钼丝材、新能源材料等的研发、生产与销售,是国内最大的钨钼产品生产与出口企业,同时也是国家级重点高新技术企业、福建省首批发展循环经济示范企业、福建省最具竞争力的上市公司和全国“十佳最具成长性上市公司”。 公司现拥有两个矿山、两个钨冶炼公司、两个硬质合金公司、四个钨钼丝材公司、一个国际贸易公司和一个房地产开发公司,打造了从钨矿山→冶炼→深加工完整的产业链,总资产130亿元。

厦门钨业主要产品包括:冶炼产品系列、钨粉末系列、硬质合金系列、钨钼丝材系列、新能源材料系列等。钨冶炼产品的生产能力达12000吨,居世界第一;钨粉末产品的生产能力为5000吨钨粉、3500吨碳化钨粉和2000吨混合料,是国内最大的钨粉、碳化钨粉生产商和出口商;硬质合金生产能力达1000吨,产品80%出口;钨钼丝材的生产能力为1500吨粗钨丝、300吨粗钼丝、100亿米细钨丝、30亿米细钼丝,产销量占全国的60%以上;新能源材料的生产能力为3500吨贮氢合金粉、1500吨钴酸锂,产销量居国内前三位。厦门钨业产品销售网络分布亚、欧、美洲等几十个国家和地区,年出口量占全国35%以上。 厦钨拥有国家级企业技术中心、博士后科研工作站,具有多项发明专利、实用新型专利和专有技术,多项核心技术处于国际领先水平,公司承担建设的多个科研项目被国家科技部认定为“国家级火炬计划项目”。

厦钨集团的信息化建设始于90年代末期,较早时采用各种财务软件,后以海沧母公司需求定制开发的“综合信息平台”,该综合信息平台仅能在一家公司使用,集团内有若干其他公司在此平台的基础上,结合各自生产经营的特点,分别独立开发,为集团各单个公司信息化建设奠定了良好的基础;在这期间,厦钨旗下的重点企业——厦门金鹭特种合金有限公司于2006年选择了微软ERP AX3.0,取得了良好的应用效果。随着时间的推移,对于单个企业应用的管理系统,无论是综合平台还是其他的软件产品在满足集团化发展的需要方面逐渐显现瓶颈态势,各个公司信息化建设的预算的申请也在逐年升高。选择一套既符合集团化发展需要,又能满足各个不同行业经营管理特性的ERP系统迫在眉睫,经过长达近一年的考查与选型,厦钨最终选择了微软ERP——Dynamics AX2012。

在项目战略规划阶段,厦钨高级管理层提出了项目实施的三大目标与三个提升:

三个目标:

各公司财务业务一体化系统

集团财务统一的共享平台

集团数据分析比较平台

三个提升:

提升公司信息化水平,缩减公司间差距、缩减与先进水平的差距

提升公司核心业务、核心流程、管理控制

提升信息化促进管理工作

为保证项目的成功实施,厦钨从集团总部与各分子抽调了50多个的专职成员为整个集团服务,各分子公司专职的项目实施人员超过200人,各公司项目小组组长均为副总以上级别,厦门一维天地也派出近30人的顾问团队。

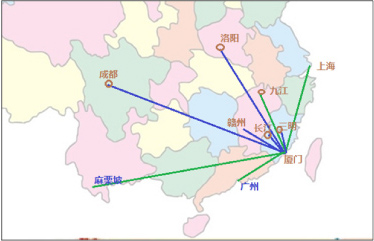

整个项目分三个阶段进行。第一阶段实施从2012年3月至2013年1 月,完成了以厦门钨业海沧公司(四位一体)、福建长汀金龙稀土、厦门虹鹭钨钼、三明宁化行洛坑(钨矿),成都虹波钼业等几个核心采掘企业、制造企业的基础模块的运用。第二阶段从2012年12月1日至2013年9月18日,将第一阶段的成果为模板在全集团剩余企业进行复制推广。第三阶段,从2013年6月起,着手进行集团化管理、分析报表与商务智能功能的实施。

解决方案

项目收益及总结

通过实施,厦门钨业不但解决了实施前各分子公司IT信息化建设各自独立建设、重复建设的状况,加强了集团内部沟通,减少了人工操作误差,加快了财务管理上信息流程与管理层需要的决策信息的速度,还大大提高了厦门钨业的经营风险规避能力,强化了集团对各子公司企业管理流程,使厦门钨业的市场竞争能力大大提高。

总结

面向冶金行业的Microsoft Dynamics AX可以在保持最低的总体拥有成本(ROI)的同时,通过附加功能进行产品定制,企业可以在承担更低风险、更小费用投入的条件下,逐步调整升级其解决方案。通过高度灵活、分层的体系架构,微软的合作伙伴能够为Dynamics AX产品线提供极具价值的定制与扩展,全面满足独特的冶金制造的要求。

微软相信,面向冶金行业的Dynamics AX解决方案可以帮助冶金行业企业确定更加有效的方式,从而更好地实施最佳实践,与其扩展的供应链上下游进行交流,使用实时的信息洞察业务情况,在大数据时代的今天更迅速地把握新业务机会。